Supplied Products: Façade Panel , Curtain Wall Panel, Cladding Panel,Steel Cladding,Metal Insulated Siding, Thermal Insulated panel for Wall & Roof , Fire Resistance panel, Cold Room Panel,Clean Room Panel, PUR/PIR Sandwich Panel, Rockwool/ EPS Sandwich Panel, Steel Sandwich Panel. Architectural Facades, External Cladding,Decorative Facade,Embossed Insulated Wall

Delivery Time: 2012

Project Location:Turkey

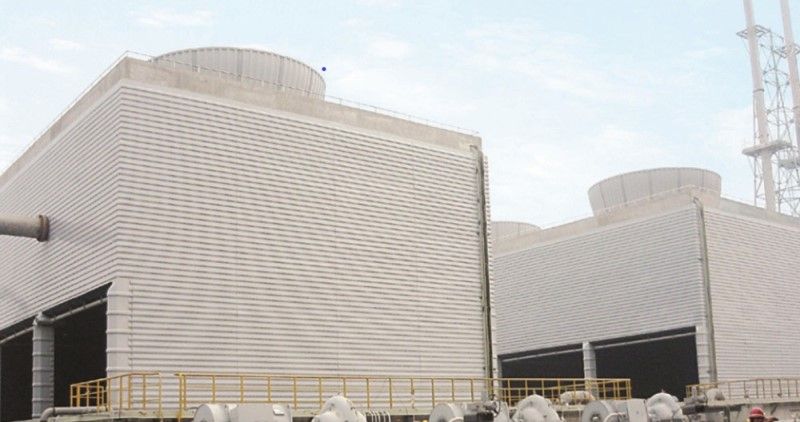

Introducing the Insulated Panel of Power Plant by KUKU Panel—engineered for power plants and critical infrastructure including airport facilities. Our Insulated Panel of Power Plant is designed for superior fire resistance, thermal efficiency, and structural durability, meeting rigorous international standards from the very start.

KUKU Panel specializes in high-performance insulated panels tailored to power plants and airport environments. Our Insulated Panel of Power Plant solutions incorporate advanced core materials such as fire-retardant PIR/PUR and Rockwool/EPS, paired with durable galvanized steel or aluminum facings. With applications ranging from power plant walls and roofs to airport auxiliary buildings, our panels deliver unmatched energy efficiency, fire safety, and ease of installation.

| Parameter | PUR/PIR Panel | Rockwool Panel |

| Core Material | Polyurethane/Polyisocyanurate | Mineral Wool (Rockwool) |

| Thickness Range | 40–200 mm | 50–200 mm |

| Thermal Conductivity | 0.019–0.025 W/m·K | 0.035–0.045 W/m·K |

| Fire Rating | Class B-s1,d0 | Class A1 (Non-combustible) |

| Density | 40–45 kg/m³ | 100–150 kg/m³ |

| Surface Finish | PVDF, Polyester, Embossed | Galvanized Steel, PVDF |

| Operating Temperature | -50°C to +120°C | -50°C to +750°C |

Superior Insulation: With low thermal conductivity (0.019–0.025 W/m·K for PUR/PIR cores), our Insulated Panel of Power Plant maintains stable indoor temperatures and reduces HVAC costs.

Fire Safety: Designed to achieve fire resistance classes up to EI 120 (with Rockwool cores) while complying with EN 13501 and ASTM E84 standards.

Structural Integrity: High load-bearing capacity (1.5–5.0 kN/m²) and corrosion-resistant steel skins ensure robustness in harsh environments.

Weather & Chemical Resistance: UV-resistant coatings and PVDF finishes protect panels in coastal, industrial, or high-traffic settings.

Lightweight & Modular Design: Facilitates rapid installation and easy transport, ideal for both new builds and retrofits.

For optimal performance of our Insulated Panel of Power Plant solutions, careful installation is paramount. Pre-installation checks should verify panel dimensions and load requirements, ensuring substrates are clean and level. Panels are secured using corrosion-resistant fasteners and sealed with appropriate silicone or butyl tape to maintain thermal integrity. Reinforced edges, particularly in high-wind zones, are addressed with fire-rated fasteners and L-shaped steel brackets.

Backed by over 25 years of expertise, KUKU Panel provides comprehensive support for its Insulated Panel of Power Plant installations, including on-site training, technical assistance, and post-installation inspections (such as thermographic fire integrity tests). Our facilities comply with ISO 9001, CE, and TÜV certifications, and our dedicated logistics network ensures timely global delivery.

Successful projects include a major airport terminal in Singapore and power plant upgrades in diverse climates. Our panels have delivered significant energy savings, enhanced fire safety, and robust structural performance in demanding applications.

Our sandwich panels are used in facades, roofs, partition walls and ceilings. The most typical applications include industrial and commercial buildings, school, sports halls, residential building, warehouses and power plants, etc. The panels are also suitable for food industry construction.

KUKU Panel's Insulated Panel of Power Plant solutions set the benchmark for critical infrastructure, combining advanced thermal insulation, excellent fire resistance, and ease of installation. Trust our proven expertise and global support to provide the best Insulated Panel of Power Plant for your facility—from the initial planning phase right through to the final installation, ensuring safe, energy-efficient, and durable operation.