Introducing KUKU, a pioneering force in the realm of insulated, fire-rated, and architectural facade systems, as well as state-of-the-art roofing systems in China. As a beacon of innovation, our mission is to redefine excellence in construction, and our unwavering commitment is encapsulated in our flagship product: THERMAL INSULATED WALL PANELS.

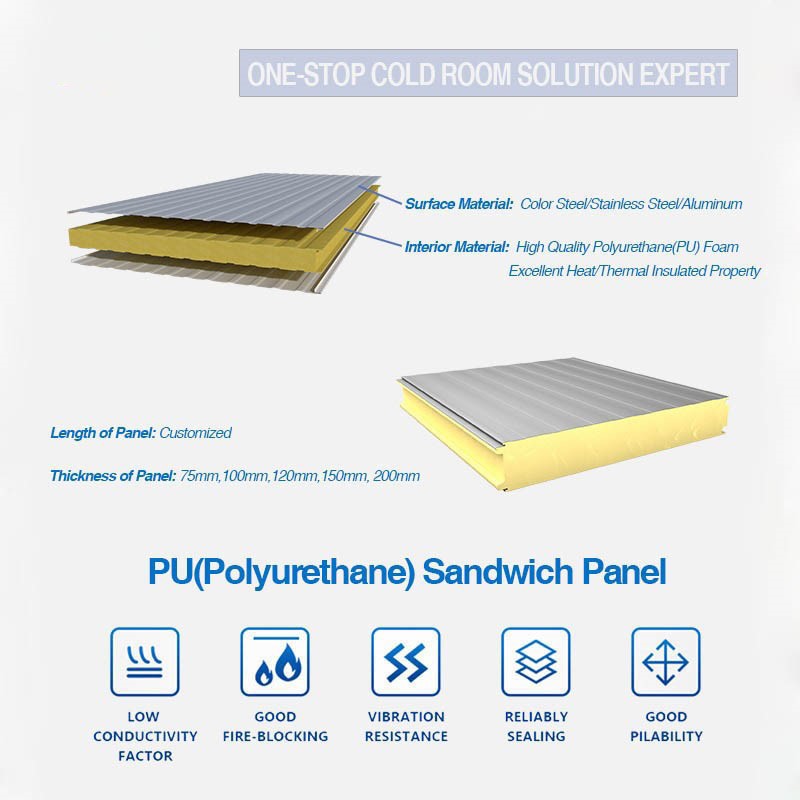

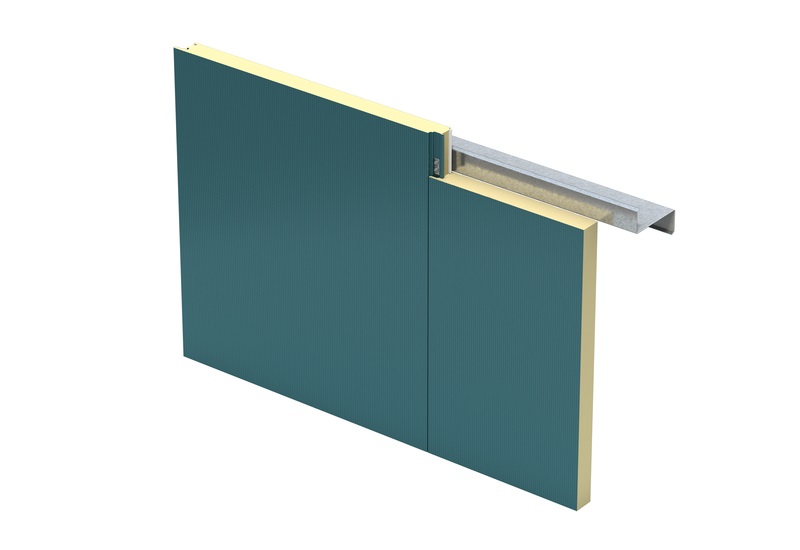

The sandwich panels with insulating core in rigid plastic foam (PUR & PIR), consist the ideal solution for façade claddings and partition walls with increased thermal insulation requirements. This fireproof building material is easy and fast to install vertically or horizontally and is available in a variety of products and applications with a range of colours and profiles.

The insulated metal panels are eco-friendly products and highly sustainable for construction. The core of each panel is made from polyurethane (PUR/PIR), which is environmentally friendly. Since our insulated metal panels have a high R-Value, it allows for building constructed by Splend to have an improvement in energy efficiency.

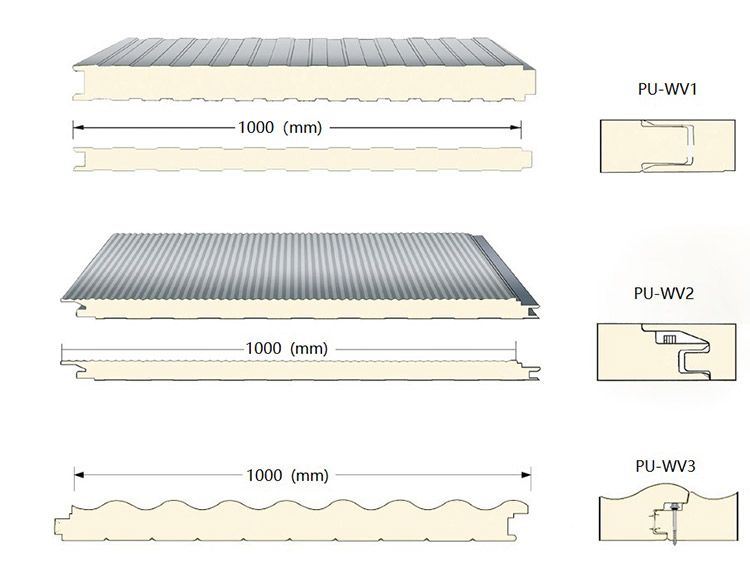

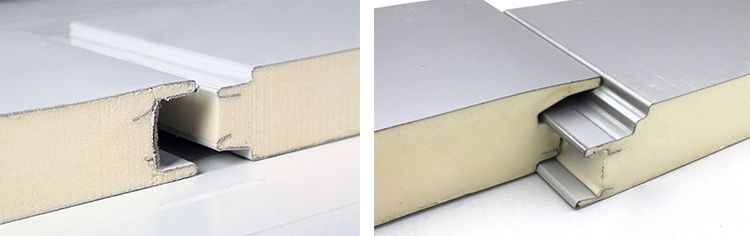

The outer layer of splend insulated metal panels consists of color Steel on each side that sandwiches the pu foam core. The edges of each sp insulated metal panel have a “Z-lock” snap to install design that allows our panel systems to eliminate thermal bridging, otherwise known as heat loss.

▼Energy-saving, Eco friendly

▼Fireproof (Class B1)

▼Waterproof, Wetproof

▼Sound Insaltion

▼Easy & Fast Installation

▼Heat Insulation & Preservation

▼Lightweight Economy

1. Excellent Thermal Insulation

One of the standout features of PU panel walls is their superior thermal insulation properties. The polyurethane core has a low thermal conductivity, which helps to minimize heat transfer between the inside and outside of the building. This ensures that the indoor environment stays comfortable while reducing the need for heating and cooling systems, leading to energy savings and lower utility bills.

2. High Strength and Durability

PU panels are designed to be strong and durable, providing excellent structural integrity. The layers of metal (typically steel or aluminum) on either side of the polyurethane core add significant strength, making PU panel walls resistant to impact and wear. This durability makes them ideal for buildings that require long-lasting performance, especially in areas with extreme weather conditions.

3. Lightweight Construction

Despite their strength and insulation properties, PU panel walls are lightweight, which simplifies transportation and installation. Their reduced weight reduces the overall load on the building’s structure and foundation, making them an efficient option for a wide variety of construction applications.

4. Fire Resistance

Polyurethane foam is inherently resistant to fire, and when combined with metal cladding, PU panels provide a fire-resistant solution for building walls. While not completely fireproof, PU panels offer a degree of fire resistance, helping to slow the spread of flames and contributing to the overall safety of the building.

5. Sound Insulation

PU panels also provide soundproofing benefits due to the dense polyurethane core, which helps to absorb and reduce noise transmission. This feature makes them particularly valuable in commercial and industrial buildings where sound control is important, as well as in residential buildings for enhanced comfort.

6. Weather Resistance

The metal facings of PU panels are highly resistant to external elements such as rain, wind, and UV radiation, contributing to the weatherproof nature of the wall system. This makes PU panel walls ideal for both indoor and outdoor applications, with minimal risk of deterioration over time.

7. Aesthetic Flexibility

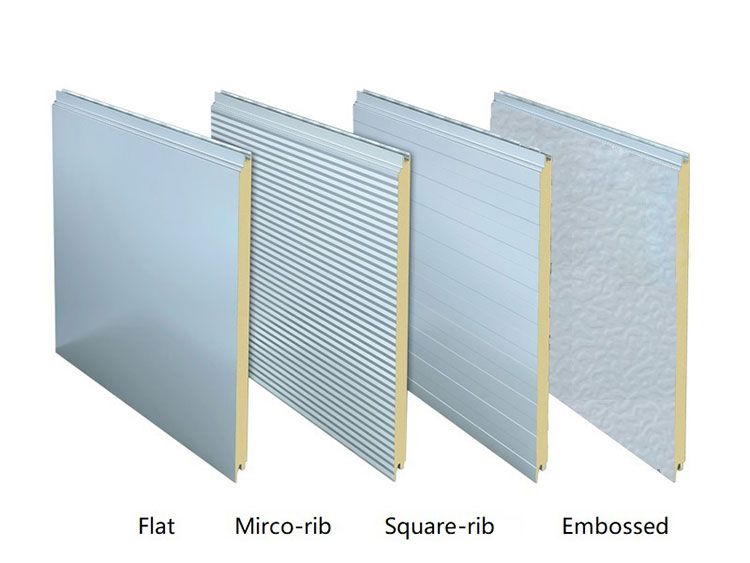

PU panels are available in a range of finishes, colors, and surface textures, making them versatile for various architectural styles. Whether you're designing an industrial facility, a modern office building, or a residential space, PU panels can provide the desired aesthetic appearance while maintaining functionality.

8. Easy Installation

PU panels are designed for easy and quick installation. Their lightweight nature, coupled with interlocking edges, allows for fast assembly and reduces labor costs. The panels are typically pre-manufactured to the required specifications, which also minimizes the time spent on-site during construction.

The Thermal Insulated Wall Panels are applied as external walls and internal division walls, installed vertically or horizontally on single- or multi-span structure.

▼Industrial halls

▼logistic centers

▼Offices

▼Clean Rooms

▼Warehouses

▼sport halls

▼Food Processing

▼Food Preparation Areas

▼Commercial Buildings

Due to their excellent insulation properties and structural strength, PU panel walls are used in a wide range of applications, including:

Industrial Buildings: Factories, warehouses, and cold storage facilities benefit from the thermal insulation and durability of PU panel walls.

Commercial Buildings: Office buildings, shopping centers, and retail stores use PU panels for energy-efficient and aesthetically appealing facades.

Residential Buildings: Homes and apartments use PU panel walls for efficient insulation and soundproofing.

Refrigerated Storage: Due to their excellent thermal properties, PU panels are often used for the construction of cold storage rooms and refrigeration units.

At KUKU, we recognize that every detail counts when it comes to architectural perfection. Our Thermal Insulated Wall Panels go beyond aesthetics and functionality – they embody meticulous craftsmanship in their installation. With two distinct fixing options – Visible Fixing and Concealed Fixing – we ensure that your architectural vision is realized with precision, stability, and finesse.

The Visible Fixing method brings forth a sense of rugged elegance. As each panel is secured to the structure, the fixings are intentionally exposed, creating a dynamic interplay between the panels and their hardware. This method is ideal for designs that seek to make a bold statement, where the hardware becomes an integral part of the aesthetic narrative.

For those who prioritize a seamless and uncluttered visual appeal, our Concealed Fixing method offers a solution of refined sophistication. Here, the fixings are ingeniously concealed behind the panels, leaving a clean and sleek surface unmarred by visible hardware. This method is perfect for designs that demand a polished, uninterrupted finish.

Surface texture is a key feature of fireproof building materials. The design and selection of fireproof building materials texture need to consider not only the basic thermal properties of the material, but also the appearance, durability and construction feasibility of the material. Different types of surface textures can produce different thermal and visual effects. Contact us to help you develop the most suitable solution.

| Product Core Options | PUR/PIR |

| Core Thickness | 40/50/60/75/80/100/125/150/200/220mm |

| Core Material Density | 40 ±2kg/m³ |

| Steel Thickness | 0.3mm-0.8mm |

| Cover Width | 400-1150mm |

| Lengths | Not more than 11.8m for container |

| Metal Type | Hot dip zinc/, Al-Zn coated/ stainless steel/ /aluminum coated |

| Steel Option | BlueScope, Baosteel, Union steel, YIEH PHUI, etc. |

| Coating Option | PE/PVDF/SMP/HDP |

| Colour Option | RAL Colour or Custom Colors |

| Fire Resistance | Non-flammable |

| Fire Rating | Grade B1 |

| Fixing details | Visible fixing and concealed fixing |

| Profile | Flat,Micro-rib, Square-rib, V8-rib, Wave and Embossed |

1, First of all, it must carry on the construction preparation before installation, include personnel, materials, etc. All will be well prepared.

2, Before the installation of PUR/PIR wall panel, it should check whether the verticality and levelness of metope purlin installation requirements, wall frame column vertical degree meets the requirement.

3, Before installation PUR/PIR wall panel, it should first mounting plate bottom water retaining plate and the bottom of the window to block water board, water retaining plate and wall frame beam connection with self tapping screw fixation.

4, PUR/PIR wall panel links with ground.

KUKU is China's largest manufacturer and installer of thermal insulation, fire protection, building curtain wall systems and roofing systems. We have more than 60 production lines to meet your different panel requirements.

With more than 10 years of production experience, advanced technology and quality service, we provide you with the highest quality solutions. Applications for our products include industrial and commercial buildings, stadiums, agricultural buildings, the food industry and residential buildings.

KUKU Your trustworthy pu panel wall supplier. Contact us now!

Q: May we visit your factory?

A: Sure, you’re welcomed to our factory any time.

Q: Can we get samples?

A: Sure. We can supply the free samples.

Q: How long can we expect to get samples?

A: Samples will be sent out within 3-5 days.

Q: Can we order products of different colors?

A: Sure. We can produce according to the customer's requirements.

Q: What is the delivery time?

A: 3-5 days. Customized products 15-30 days.

Q: What are the terms of payment?

A: T/T.

Q: What is your MOQ?

A: 300 m².

Q: How do you check all the goods in the production line?

A: We have spot and finished product inspection.